Semiconductor

| Maker | Type | Model | Note |

|---|---|---|---|

| LRC | Rainbow | 4420, 4520 | Overhaul |

| Standalone | 9400SE, 9600SE | Refurbish | |

| Alliance | 9400SE, 9400PTX, 9400DFM, 9600PTX EXELAN HPT | Conversion |

SHUTTER MODIFY(300mm SEMES)

SHUTTER MODIFY(300mm SEMES)

◆ ESC Dechucking system(200mm LAM EXELAN/HPT)

PIt is a system to prevent Wafer broken and Sliding due to Sticking after the completion of the process and is applied to the entire 200mm line equipment of “S” company.

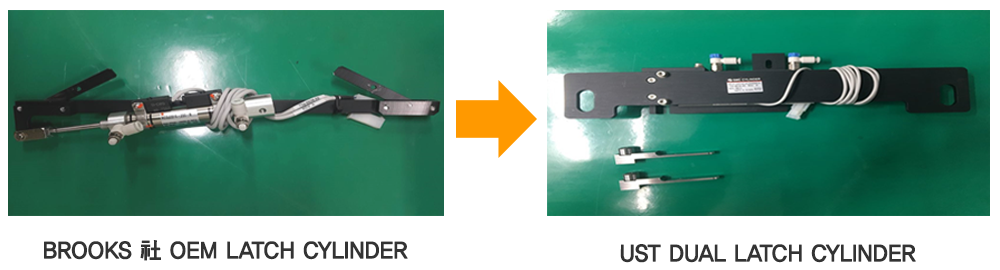

◆ 300mm LAM LOADPORT LATCH CYLINDER & LATCH HOLDER

Latch and Latch Drive Cylinders involved in wafer foup open/close loadport of Blooks as a part of LAM facilities

The product that has been modified and improved from the existing single cylinder to the dual cylinder

The product was developed since driving errors occur due to frequent air leakage of the OEM cylinder

◆ 300mm LAM He Iso Valve Overhaul

The valve kit entering the He ISO Line causes air leak and operation driving error due to O-ring damage inside the valve switch due to high heat and driving friction inside the C/B

As a result, proceed ovehaul and CAP modification improvement inside the switch (LED LAMP is installed on the drive detection sensor, and sensing status can be checked with the naked eye)

Better cost savings compared to OEM MAKER VALVE and visual inspection of valve operation

With its own JIG and He Detector, it is possible to deliver quickly after the Leak Confirm and Drive Test (KIYO E/X, KIYO 45, D/S, Multiple models, such as F/X)

| Overhaul Before | |||||

|---|---|---|---|---|---|

Body 내부 |

Flange |

Flange |

Angle 내부 |

Disassemble |

|

| Overhaul After | |||||

Body 내부 |

Flange |

Flange |

Angle 내부 |

Assemble |

|

| Leak Check | |||||

|

Flange |

Flange |

Body (Open) |

Body (Close) |

|

| CAP Change | |||||

|

|||||

- Clean room and Air shower

- Vacuum System (Dry pump, Moving Oil pump)

- Cooling System (PCW, DI)

- Gas Supply System (Air, N2, He, CF4, O2 and etc.)

- Equipment Power System (3Φ 208V+N)

- He Leak Detector